FROM THE PROJECT IDEA TO STARTING THE DEVICE AND ON

Every project has its life cycle. A request is substantiated into a project work and followed by projection, coordination and optimization of the device. After the customer has confirmed the project, production can start. The device is built in, wired and set up pneumatically and electrically. In the presence of the customer, it is checked for its functions. For delivery to the customer, it is dismantled to the stage the device is suitable for transport at. Equipment packed according to transport requirements is delivered to the customer where it is assembled and wired again. The equipment is started and handed over to the customer. In case of technical problems or malfunctions of the device during its lifetime, our technical team will always be happy to help you.

During the device operation period, the customer can be provided with spare (wearable) parts of the device.

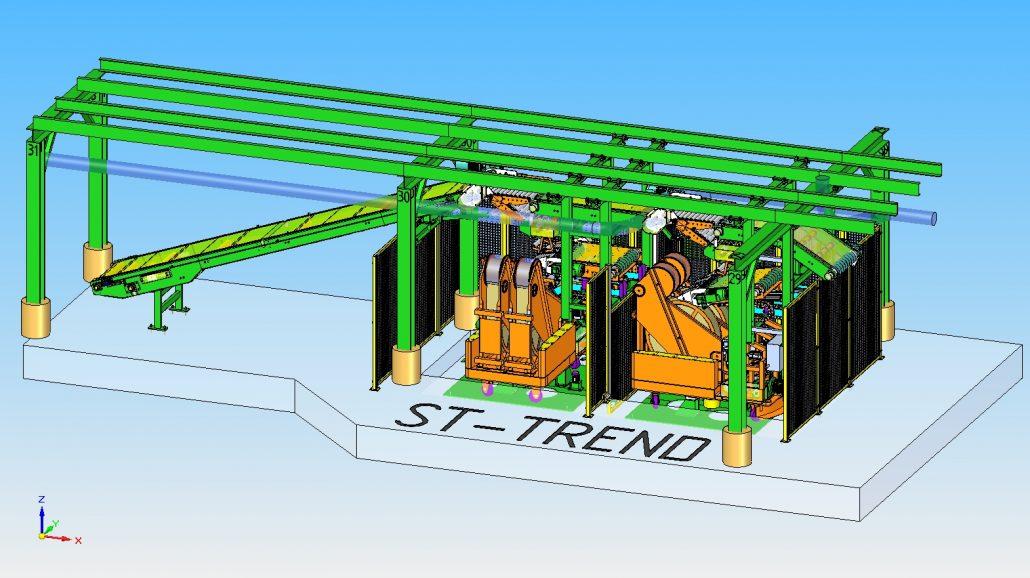

The main activities of the company are projection, production and installation of machines, machine lines and machine parts.

Temporarily we are mainly involved in:

- the car tyre manufacturing process

- the air spring manufacturing process

- the mineral wool manufacturing process

We also produce and install machines, machine lines and machine parts for other industries, using our own or the customer’s documentation.